Poly(adipate)ester TPU Resins

Poly(adipate)ester TPU Resins Specification

- Hardness

- Shore A 85-95

- Packaging Type

- Laminated bag

- Form

- Granules

- Material

- Poly(adipate)ester Thermoplastic Polyurethane (TPU)

- Thickness

- Customizable

- Usage & Applications

- Shoe soles, hoses, cable jackets, films, industrial components, sporting goods

- Type

- Thermoplastic Elastomer Resin

- Material Feature

- High flexibility, abrasion resistance, hydrolysis resistance

- Density

- 1.22 Gram per cubic centimeter(g/cm3)

- Grade

- Industrial grade

- Tensile Strength

- 35-45 MPa

- Melting Point

- 155-180C

- Weight

- 25 kg (standard bag)

- Color

- Milky white

- Shelf Life

- 12 months

- Water Absorption

- <0.2%

- Processing Method

- Injection molding, extrusion

- Odor

- Odorless

- Elongation at Break

- >400%

- Transparency

- Semi-transparent

- Storage Condition

- Cool dry place, away from sunlight

- Abrasion Loss

- <30 mm³

Poly(adipate)ester TPU Resins Trade Information

- Minimum Order Quantity

- 300 Containers

- Supply Ability

- , , Container

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Poly(adipate)ester TPU Resins

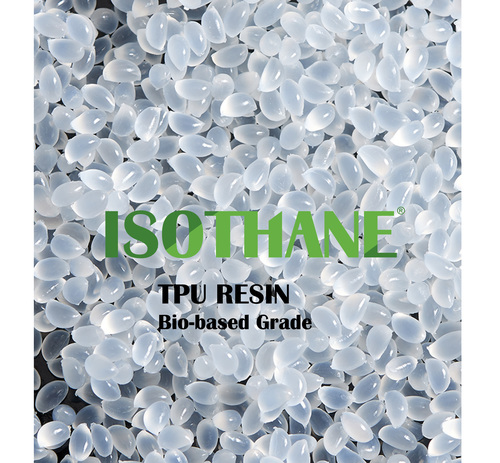

Poly(adipate)ester TPU resins

ISOTHANE 1000 series resins are polyester based thermoplastic polyurethane. They exhibit excellent transparency, mechanical properties, abrasive resistance, and solvent resistance. ISOTHANE 1000 series can be processed by extrusion and injection molding.

Exceptional Performance for Demanding Applications

This poly(adipate)ester TPU resin offers superior mechanical properties, including high elongation, tensile strength, and abrasion resistance. Its industrial-grade quality ensures reliability in demanding environments, making it a preferred choice for shoe soles, cables, hoses, and sporting goods. Users benefit from its hydrolysis resistance and low water absorption, which enhance product lifespan and toughness.

Versatile Processing and Customization

Designed for injection molding and extrusion, these TPU resins support efficient production of components with varying thicknesses and shapes. Their customizable properties enable tailored solutions for diverse end-uses, and their semi-transparent, milky white appearance allows for flexibility in final product design. This versatility delivers added value across multiple industries.

FAQs of Poly(adipate)ester TPU Resins:

Q: How should Poly(adipate)ester TPU Resins be stored to maintain quality?

A: Store these TPU resins in a cool, dry place away from direct sunlight to prevent degradation. Always keep the granules sealed in their laminated bags when not in use to ensure optimal shelf life of up to 12 months.Q: What are the main benefits of using Poly(adipate)ester TPU Resins?

A: The resins provide high flexibility, superior abrasion resistance, great hydrolysis resistance, and low water absorption. These features make them suitable for robust, long-lasting products across multiple industries, including footwear and industrial goods.Q: When is it recommended to use Poly(adipate)ester TPU Resins in manufacturing?

A: Use these resins when high elongation at break, excellent tensile strength, and durability against abrasion are required in your products, such as shoe soles, cable jackets, hoses, and sporting goods.Q: Where are Poly(adipate)ester TPU Resins commonly applied?

A: The resins are widely used in manufacturing shoe soles, hoses, cable jackets, functional films, industrial components, and sporting goods due to their versatile and tough material properties.Q: What processing methods are suitable for these TPU resins?

A: Poly(adipate)ester TPU Resins are optimized for injection molding and extrusion, allowing for efficient production of a wide range of components with customizable thickness and shapes.Q: How does the low water absorption property benefit end products?

A: Low water absorption (<0.2%) ensures that finished goods maintain structural integrity and performance even in humid or wet environments, extending product lifespan and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ISOTHANE TPU Resins Category

Flame Retardant Grade

Minimum Order Quantity : 30 Containers

Grade : FR Grade

Type : Other, Flame Retardant Grade

Color : Natural

Material Feature : Halogen Free, High Impact Strength, High Heat Resistance, UV Stabilized

Biocompatible Grade

Minimum Order Quantity : 1 , , Container

Grade : Medical Grade

Type : Other, Biocompatible Grade

Color : White

Material Feature : Nontoxic, High Purity, Sterilizable

Expanded TPU

Minimum Order Quantity : 1 Container

Grade : Expanded TPU

Type : Other, Thermoplastic Polyurethane (TPU)

Color : White

Material Feature : Lightweight Flexible Durable

High Moisture Vapor Transmission Grade

Price 1 USD ($) / Container

Minimum Order Quantity : 1 , , Container

Grade : High Moisture Vapor Transmission Grade

Type : Other, Polymer beads

Color : Blue

Material Feature : Moisture resistance

Send Inquiry

Send Inquiry